Hat channels come in a variety of materials and sizes, and they can be used in applications with specific projects. When it comes to renovating or rebuilding the walls and ceilings of your basements, it is necessary to understand how to use the correct hat channel for furring. Most basement renovation projects include masonry walls and possibly even ceiling assemblies. Depending on the type of wall you are going to build, whether it’s a concrete wall or drop ceiling, you can insert your hat channel in a variety of different ways.

What is a Hat Channel?

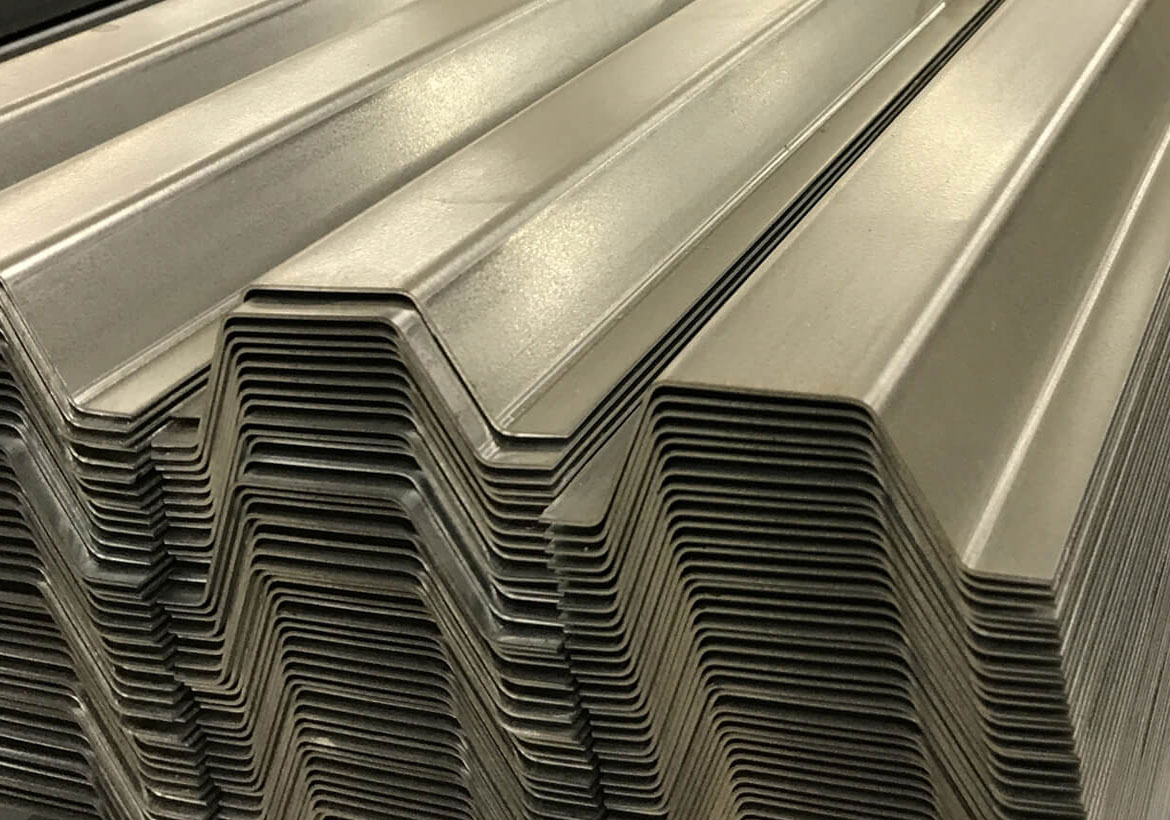

A hat channel is a corrosion-resistant framing piece, which is used to fur out walls in masonry and ceiling projects. While it is most commonly used in basement renovations, it is used in other applications as well.

Hat channels get their name from their hat-like shape. Hat channels contain a grooved metal piece which is perfect for leveling out walls. The shape is also ergonomically-friendly, making it easy to install without much hassle at all.

Hat channels can be made from a variety of different materials, including steel and aluminum. Hat channels are heavily sought after by masons and builders as this is the most affordable way to even out walls. Not only do they provide advantages in the construction process, but they also protect your interior and exterior frames from fire, moisture, corrosion, and other dangerous hazards.

Hat Channel Sizes

The most common hat channel sizes typically range from a ⅞” furring channel to a 1 ½” furring channel. The deeper the channel, the higher the capacity it can hold. Hat channels are usually measured in millimeters or inches, and allow for good amounts of loading capacity for any sized project. The best way to determine the perfect size for your hat channel is to understand the thickness of your walls as well as the dimensional requirements by the clips you are going to attach the channels to.

Furring channels or hat channels are usually available in the standard sizes and dimensions that you’ll find at your local retail store. However, if you are expanding your basement or creating a customized room, you may want to invest in some special orders. Remember that aluminum hat channels are best for cutting, so you might want to go down that route if you find that the dimensions of your walls and ceilings are nowhere near the standard measurements.

Hat Channel Dimensions

Dimensions of hat channels vary depending on your furring project. We’ve gathered some statistics on a few of the most standard lengths and depths that you can easily find at your local hardware store or retailer. While different types of hat channels may require different dimensions, you can easily follow the table below to get a good feel for the average sizes you’ll be working with.

Here are a few of the standard sizes you’ll find:

Lengths:

- 10’ long

- 12’ long

Depths:

- 25-gauge

- 20-gauge

- 18-gauge

- 16-gauge

Of course, there are always alternative sizes available depending on the uniqueness and complexity of your project. Basement renovations can sometimes require custom work, in which case an off-sized hat channel may be necessary. Otherwise, you can equip standard lengths to fit across a ceiling or wall.

Metal Hat Channels

While some of the more traditional furring channels come in wood, metal hat channels have become a popular favorite among masons. Metal is found to be better for structural support and can be easily installed without damaging the other materials around it. Metal is also a preferred choice by many builders because it is fire and sound resistant.

- Steel Channels – Hat channels are available in galvanized steel, which can be used in walls or drop ceilings. Steel channels can come in heavier gauges, which makes for a greater loading capacity. If you are building a heavy-duty basement, a steel channel is the most durable, rigid, and reliable material to use. The steel is galvanized to protect it from any chance of corrosion or flames, making it a safe and long-lasting choice to bond to your ceiling or walls. Plus, they’re incredibly easy to install!

- Aluminum Hat Channels – Extruded aluminum is great for when you need custom hat channel sizes. Since this is a fairly lightweight metal, it is easy to cut, so you can special-order hat channels in the dimensions that you need. Aluminum hat channels take on the same primary functions as other metal channels, helping to even out irregular surfaces on your interior or exterior walls. This is a cheap and lightweight material to use as well. However, it’s just as fire and water-proof as the steel options.

What is Furring?

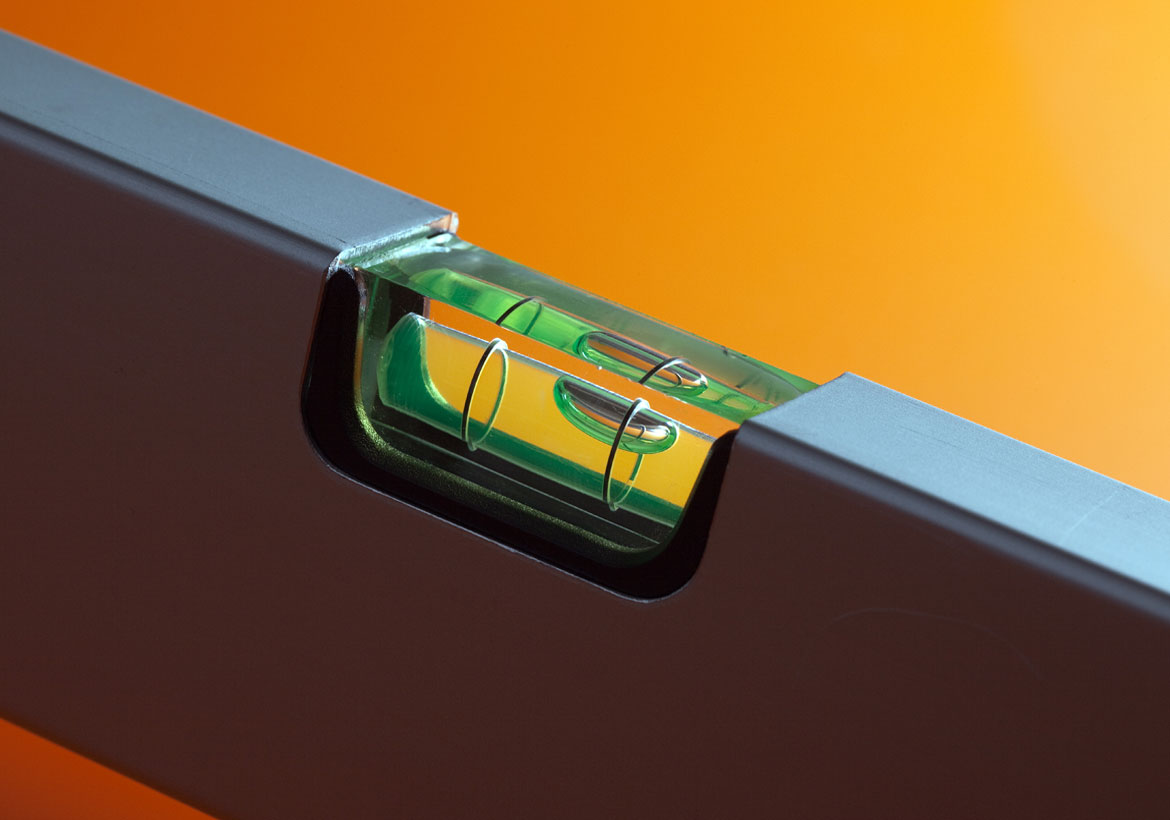

Furring is the process of raising or leveling surfaces of a wall or ceiling to make it even. This is a very necessary procedure in the construction process, as it is a requirement to make a building structurally sound. Masons will often mention furring to describe the actual process of installing strips or hat channels to a surface. Traditional furring involves the application of rectangular wooden strips across a wall or ceiling to keep it even and leveled before the application of insulation and covering.

In the application of wall furring, a construction worker or mason will lay wooden strips out perpendicular to the studs of the wall. They lay vertically against the wall if an existing surface is already present. Strip spacing depends on what material is used to finish the wall. For example, if you are using heavy boards to finish the wall, you will want to space the furring strips out more widely. If you are using plaster or paneling, you can space them closer together.

When you use hat channels to complete a furring project, rather than using wooden strips, this is metal furring. You will most commonly find metal furring applicable to the renovation of basements, although they are also used quite frequently in commercial or large industrial projects. Metal furring strips are synonymous with hat channels, and they contain a cross-section with two trapezoid-shaped flanges on either side. They can vary in thickness and dimension, as described in the section above.

Furring Strips

What are furring strips, exactly? Well, they are another term used for the strips that are used to fur masonry walls and drop ceilings. The two main types of furring strips are made of wood and metal. Wood furring strips are simpler and typically measure 50mm in length. Metal furring strips, or hat channels, come in a variety of sizes and are preferred for their increased durability and resistance to water and fire.

Resilient Furring Channel

Some hat channel brands and companies offer resilient channels, which are extremely effective not only for leveling your walls, but for drowning out sound and other inconveniences as well. It is a cross-furring channel which makes for the easier attachment of gypsum and other sound-blocking panels.

When installing resilient furring channels, be sure to place them perpendicular to the framing components within your walls and ceilings. Most reliable brands will offer resilient furring channels pre-punched, meaning that you can easily screw them into the corresponding wood or steel frames with ease.

Metal Furring Channel

All metal furring channel options are built to comply with ASTM C645, which is the standard specification for steel framing components. This works for nonstructural members, and is available as part of the Book of Standards.

It is required that metal channels and hat channels be installed the way they are meant to, in order to keep your building structurally sound and to prevent any sources of unevenness. Using metal channels is by far the quickest, easiest, and cheapest way to level out your walls and ceilings before finishing them. Plus, you have the added benefit of knowing that your metal channels (aluminum, steel, or otherwise) are completely resistant to fire and water, which will keep your basement intact should you be faced with a natural disaster or bad leak.

Build Your Basement the Right Way–with Hat Channel!

The shape and structure of hat channels alone should be enough to convince you of their ease of installation. These sound materials are perfect for screwing into framing, helping to even out existing or newly renovated walls. When deciding on the structure and look of your basement, you don’t want to be stuck worrying about uneven or unfinished walls.

While hat channels come in a great number of styles, materials, and sizes, they are installed in compliance with your wall or ceiling project. Whether your wall is concrete, or you are applying gypsum paneling as a finish, you can find the right kind of furring channel to close it up and prevent it from taking on any kind of damage.

You can easily find your hat channel options at a local hardware store, or even by searching online through reliable brands and resources. Make sure to consider what hat channels have to offer!

Other Great Articles to Read:

- The Sheetrock vs Drywall Guide: Choosing Different Types of Drywall

- Why Basement Kid Caves are the New Man Cave

- 50 Modern Basement Ideas to Prompt Your Own Remodel