Featured Image: Popular Woodworking

If you’re working on a project, an electrical job, or anything else that needs the use of hand tools and power tools, the likelihood is that you’ll need to drill holes. Generally, these holes are used to introduce screws, nails, studs, and other objects and materials into various objects and surfaces. And, as you might guess, you’ll require a drilling tool or a drilling machine to accomplish the task.

Not all drills on the market are identical since they perform distinct roles. While some are excellent for minor projects, others are ideal for heavy-duty use, and some are even portable. As a result, selecting the appropriate type of drill for your intended use and requirements might be extremely complex. Thus, we’ve compiled a list of the top drills for your toolkit or workshop. You’ll also find facts and distinctions for each of the following types of drills to help you choose the best one.

Manual (Best For Home Use)

These were the first drills invented. They turn the circular motion created physically into amplified torque, allowing you to drill holes into difficult-to-drill-through surfaces. While manual drills are not as popular as they once were due to the physical work required to use them, they are nevertheless useful to have in the house in the event of a power outage. They include the following:

BREAST DRILL

Turbo Squid

This tool works like eggbeater hand drills, only it has a plate on the rear.

BOW DRILL

Alibaba

This gadget is also known as a fire drill since it can start fires without using matches.

CRANK DRILL

Wikimedia Commons

The high helix angle of the crank drill allows it to drill deep holes in tough materials.

Powered Drills

Powered drills have motors that power their activities. They are far more powerful than manual drills and do not necessitate any physical effort on your behalf. As a result, they are suitable for serious do-it-yourselfers and professionals alike. They are as follows:

Pneumatic Drills

Pneumatic drills, sometimes known as jackhammers, are powered by compressed air. They are incredibly strong, making them perfect for heavy-duty applications like drilling in rocks or breaking up pavements. Pneumatic drills are appropriate for usage in potentially explosive situations. Among these drill kinds are:

Heavy-Duty Drills

A drill press is the greatest option if you run a workshop that handles a lot of heavy-duty drilling because they are massive and powerful. Among them are:

PORTABLE DRILL PRESS

Timber Frame Tools

It is smaller than regular drill presses, making it an excellent alternative for DIYers.

FLOOR DRILL PRESS

Amazon

The tabletop drill press is a larger and more powerful variant of the benchtop drill press.

CNC DRILL PRESS

Direct Industry

This multipurpose equipment has the ability to drill, bore, grind, and turn.

25 Different Types Of Drills

1. Eggbeater Hand Drill

This is a gear-driven drill with a rotating driving wheel that spins when the handle is rotated. Once the wheel begins to spin, the drill travels in lockstep with the chuck, which causes the bit to rotate. This manual tool excels in drilling small holes in wood and metal.

2. Breast Drills

These tools operate in a manner similar to eggbeater hand drills, with the exception that they come equipped with a plate affixed to their back. This plate enables you to provide greater drilling pressure during operation by pressing against the drill with your chest. As a result, breast drills are more effective than eggbeater hand drills.

3. Brace Drill

The brace drill features a U-shaped spindle that provides for increased torque generation when cranking. Additionally, it has another spindle at the top that allows you to hold and align the tool. When working with wood, the brace drill is used to countersink.

4. Bow Drill

This item is also referred to as a fire drill, as it is capable of starting fires without the need of matches. The bow, hearth, spindle, and bearing block are all included. It generates heat through friction, which results in the formation of an ember in sawdust.

5. Crank Drill

The crank drill’s high helix angle increases its penetration efficiency, allowing it to cut deep holes in difficult materials. Additionally, it features a sharp tip that enhances its cutting capabilities. Crank drills are one of the few manual drills that are suitable for drilling into hard metals such as steel.

6. Gimlet

A gimlet is an extended drill bit equipped with rotation handles. This tool makes use of leverage to drill deep and wide holes. By extending its handles, you can generate additional force.

7. Push Drill

The push drill is a more powerful but smaller counterpart of the hand drill. It is equipped with a spiral ratchet that is used to rotate the bit. This drill is utilized in tasks requiring a high degree of accuracy or precision in woodworking.

8. Post Drill

They acquire their name from their mounting on posts. These hand-powered presses are capable of boring holes into iron, albeit the size and depth of those holes are determined by the operator’s strength.

9. Table Drill

This general-purpose drilling machine offers a large and solid working surface for your materials. However, because it is dependent on your strength, it may not be ideal for heavy-duty drilling.

Powered Drills

Powered drills have motors that power their activities. They are far more powerful than manual drills and do not necessitate any physical effort on your behalf. As a result, they are suitable for serious do-it-yourselfers and professionals alike. They are as follows:

10. Cordless Drills

Because these machines are battery-powered, they are extremely portable and may be used anywhere. Cordless drills, on the other hand, have the lowest power output of any powered drill type. Nonetheless, there are some very strong ones that are extremely pricey. Another downside of cordless drills is their short battery life. These drills are perfect for casual home users as well as professionals working on off-grid job sites.

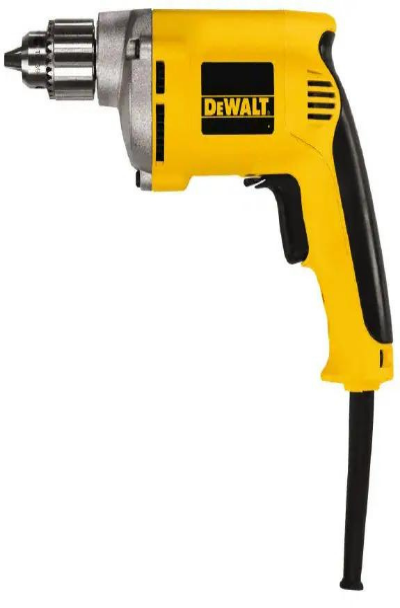

11. Corded Drills

Corded drills are more powerful and lighter than cordless drills. They must, however, be attached to a wall socket at all times in order to function, which severely limits their portability. Despite this, they are excellent electric drills for heavy-duty use in the workshop.

12. Reversible Drills

These drills may rotate both clockwise and counterclockwise. As a result, they are ideal for quickly and effectively tightening and loosening screws.

13. Impact Drills

Impact drills are ideal for heavy-duty woodworking applications. This is due to the fact that, unlike ordinary drills, impact drills begin hammering the material when they face resistance, allowing them to cut holes in tougher materials. Nonetheless, they are bad at screw fastening since they have a tendency to jam fasteners into the surface.

14. Hammer Drills

The hammer drill receives its name from its working mechanism, which is characterized by a continual pounding motion. Hammer drills, like impact drills, are awful at fastening. They are, nevertheless, quite good at drilling holes in extremely hard objects.

15. Rotary Hammer Drill

This drill is most commonly used in masonry. It has an additional grip for enhanced control. The fundamental difference between it and a standard hammer drill is that it accelerates the drill bit with pistons rather than cam plates.

16. D-Handle Drills

A D-handle drill is essentially a hammer drill with the trigger located at the rear rather than the front. D-handles are equipped with powerful motors that enable them to create continuous speed and power. They are also utilized in mixing applications, in addition to drilling.

17. Combination Drill

This instrument, sometimes known as a combi drill, can be used as both an impact and a hammer drill. As a result, it is an excellent bargain for someone who requires both. Combination drills can also be used on soft and tough materials.

18. Mechanic Drill

A mechanic drill has a versatile design that allows it to be used for both light and heavy-duty tasks. As a result, rather than purchasing separate drills for softwood and metals, a single mechanic drill should suffice.

19. Auger Drill

This is a bigger drill used to drill holes in the ground. It is available in both one- and two-person variants. The motor is located above the bit and is controlled by huge grips.

20. Core Drill

When drilling huge holes in walls or surfaces, a core drill comes in helpful. They have a secondary grip and a safety clutch for improved handling and safety.

Pneumatic Drills

Pneumatic drills, sometimes known as jackhammers, are powered by compressed air. They are incredibly strong, making them perfect for heavy-duty applications like drilling in rocks or breaking up pavements. Pneumatic drills are appropriate for usage in potentially explosive situations. Among these drill kinds are:

21. Straight Air Drills

Straight air drills have a tiny chassis that makes them excellent for usage in small locations. Furthermore, they are excellent alternatives to standard power drills since, despite their size, they produce more power.

22. Gun Handle Drill

Straight air drills are not as effective as gun handle drills. As a result, they are ideal for industrial applications. They are the most often used form of corded drill.

Heavy-Duty Drills

A drill press is the greatest option if you run a workshop that handles a lot of heavy-duty drilling because they are massive and powerful. Among them are:

23. Portable Drill Press

It is also known as a benchtop drill press and has smaller proportions than regular drill presses, making it an excellent alternative for do-it-yourselfers. It can, however, hold its own in an industrial setting.

24. Floor Drill Press

The tabletop drill press is a larger and more powerful variant of the benchtop drill press. For drilling long and solid objects, the floor drill press is suitable.

25. CNC Drill Press

This multipurpose equipment has the ability to drill, bore, grind, and turn. Because it can be programmed, it is commonly used in mass production companies to generate accurate holes.

How To Choose From Different Types Of Drills

Consider how you will utilize your drill. Before purchasing a drill, consider what you intend to use it for.

Consider the following questions:

- What surfaces will you have to drill into?

- Do you need to be able to position or hold it in a specific way (for example, at a straight angle)?

- Will you have to move around with it a lot, whether it’s climbing ladders or walking back and forth on the ground?

- How long will you need to use your drill at a time?

Answering questions like these will help you narrow down what you’re searching for in a drill.

Determine Whether You Want A Corded Or Cordless Drill

Cordless

Cordless drills are well-known for their versatility, as they are often easier to use and lighter than corded drills.

When selecting a cordless drill, keep the following factors in mind:

Power: You’ll want to keep an eye out for two metrics here: voltage and torque. The basic rule is that a greater voltage indicates a more powerful drill. The majority of cordless drills on the market today are 18V, while lower (7.2V) and higher (20V) alternatives are available.

Torque is measured in newton-metres and represents the twisting power (Nm). Some drills allow you to vary the torque settings so that you can use more torque for stronger materials and less torque for sensitive materials.

Speed will be measured in revolutions per minute (rpm). Many drills have two speeds (300rpm for drilling and 800rpm for screw driving), but choosing a drill with variable speed settings (including speeds up to 1,000rpm) will give you greater control.

Batteries: One of the most popular forms of batteries today is lithium-ion, which charges faster, lasts longer, and is lighter than other types such as NiCd (Nickel-Cadmium). Lithium-ion batteries also offer continuous drain until the power is totally depleted.

Keep two things in mind: the battery charger and the battery’s Amp hour (Ah). Some chargers can recharge a battery in as little as 15 minutes. Others will take three hours, a significant variance that can have a significant impact on your productivity. Another important parameter that provides you an indication of a battery’s storage capacity. A greater Ah value, once again, generally signifies a longer battery life.

Corded

Corded drills are suited for heavy-duty applications. When it comes to finding one, there are several variables to consider. Some are similar to cordless drills (torque and speed), but you must also consider:

Power is measured in watts for a corded drill. Higher wattage, like higher voltage, indicates a more powerful drill.

SDS (Special Direct System) drills concrete are designed to hammer with greater force. This allows you to complete more difficult tasks faster, and you can even add chisel bits to turn your SDS drill into a mini-jackhammer (breaking through concrete, removing tiles, and other light demolition projects). They are the best drill for concrete.

Whatever drill you choose – whether a cordless drill driver or a corded hammer drill – what matters is that you select the drill that is most suited to your needs and is ready to assist you in getting the job done.

Content

Keeping all of the different types of drills mentioned above in mind, you should be able to pick the proper one rather easily. This is owing to the fact that each of the numerous sorts of drills mentioned here has its own set of details, advantages and disadvantages, and even differences. As a result, you should be able to fairly select the proper one for your purposes and effortlessly drill the holes that you require. If you have gone through all of these drills, please share your feedback in the comments area. You can also post any queries you have down there!

This is an image roundup post, curated to showcase and promote other reputable contracting companies’ and their amazing work. To have any of the images removed, please reach out to us and we would be happy to do so.